-

- Contact Us

- Privacy Policy

- term and condition

- Cookies policy

GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

Manufacturer app notes and vendor benchmarks show hybrid 650V IGBT + SiC SBD topologies can cut switching losses by as much as 30–60% versus legacy diode‑IGBT pairings, yielding measurable system efficiency gains in mid‑voltage inverters. This article provides a detailed electrical, thermal and integration analysis for the GTSM40N065D when paired with SiC Schottky barrier diodes (SiC SBD): datasheet‑driven static characteristics, measured switching loss breakdown, thermal and reliability implications, and practical gate‑drive and layout guidance for prototype and production designs. The treatment includes calculation templates, test methodology (double‑pulse/clamped inductive), and a comparative case study so engineers can reproduce and quantify gains in their own 650V inverter designs.

Background: GTSM40N065D and the hybrid 650V IGBT + SiC SBD approach

Device overview: GTSM40N065D key ratings and package

Point: The GTSM40N065D is a 40A / 650V IGBT offered in a discrete package with specific thermal, conduction and gate‑charge characteristics that drive both layout and cooling choices. Evidence: The product listing and manufacturer datasheet specify Vces = 650V, Ic (cont.) ≈ 40A, typical Vce(on) at specified Ic, Rth(j‑c) and gate charge Qg. Explanation: For design work the most relevant numbers are Vce(on) at operating current (for conduction loss), Qg and Qgs for gate‑drive sizing and switching loss, and Rth(j‑c) plus recommended mounting for thermal design. Link: Refer to the GTSM40N065D datasheet entry on major distributor/manufacturer pages for exact tabulated values and waveform examples from the vendor.

Why pair a 650V IGBT with a SiC SBD

Point: Replacing a fast silicon freewheel diode with a SiC SBD alongside a 650V IGBT reduces reverse‑recovery losses and eliminates recovery current spikes. Evidence: Si diodes exhibit significant reverse recovery charge (Qrr) that interacts with IGBT tail current and causes large turn‑off energy; SiC SBDs have negligible Qrr and lower forward drop at high temperature, reducing both Esw and conduction losses during freewheel intervals. Explanation: In hard‑switching or clamped‑inductive transitions the absence of a recovery spike reduces peak dI/dt and associated ringing, lowers turn‑off energy in the IGBT, and relaxes snubber demands — making SiC SBDs attractive in inverters, motor drives and PFC stages where switching loss reduction yields smaller heat sinks and higher efficiency.

Fundamental switching behavior of 650V IGBTs

Point: 650V IGBTs show characteristic tail currents and Miller‑region behavior that dominate turn‑off losses and EMI. Evidence: During turn‑off the carrier removal generates a tail current; the gate‑collector capacitance and Miller effect slow Vce rise when the collector voltage traverses the Miller plateau, and the stored charge and tail set turn‑off energy. Explanation: Important measurements include turn‑off tail duration, Miller plateau voltage and time, Vce(t) slope (dV/dt) during transition, and waveform synchronization between diode current decay and IGBT collector current. These determine the gate‑drive strategy and snubber sizing needed to control losses and EMI without inducing unacceptable switching stress.

Key electrical specs & static performance (data-driven)

On-state characteristics and Vce(on) implications

Point: Vce(on) directly sets conduction loss and influences thermal design. Evidence: Use the datasheet value for Vce(on) at the target Ic and temperature to calculate Pd_conduction = Ic_avg × Vce(on) × duty_fraction. Explanation: Example template: For a half‑bridge leg carrying 30A average at 50% duty with Vce(on)=1.7V, conduction loss per device = 30A × 1.7V × 0.5 = 25.5W. Designers must add temperature‑dependent Vce(on) derating and worst‑case current ripple to select Rth and heatsinking. Actionable: Measure Vce(on) across expected temperatures and apply a safety margin (e.g., +20%) for continuous operation when specifying heatsink and copper area.

Off-state and blocking characteristics

Point: Leakage and breakdown margining determine safe bus voltage headroom and derating strategy. Evidence: Datasheet BVces(min) and leakage vs temperature curves show reverse leakage growth; gating‑off leakage multiplied by ambient temperature sets idle dissipation and must be integrated into standby thermal budget. Explanation: For 650V systems aim for a margin (typically 10–20%) between max DC bus and BVces(min) at elevated temperature; include avalanche and SOA notes from the manufacturer to select safe operating envelope and gate‑drive protections. Actionable: Validate leakage and blocking at intended ambient and junction temperatures to ensure safety margins for series stacking or high‑transient environments.

SiC SBD static metrics that matter

Point: SiC SBD forward Vf and leakage vs temperature are critical for freewheel conduction and standby losses. Evidence: Typical SiC SBDs used with 650V IGBTs show lower Vf at high current compared to silicon diodes and extremely low Qrr; leakage increases with temperature and must be accounted for on 650V rails. Explanation: Lower Vf reduces freewheeling conduction loss during inverter off intervals, and negligible recovery prevents turn‑off energy spikes. Actionable: Choose SiC SBDs with adequate reverse‑voltage rating (≥ bus voltage × margin) and forward current rating matched to peak freewheel currents; verify thermal coupling and mounting compatibility with the IGBT package.

Dynamic switching behavior & measured loss breakdown (data analysis)

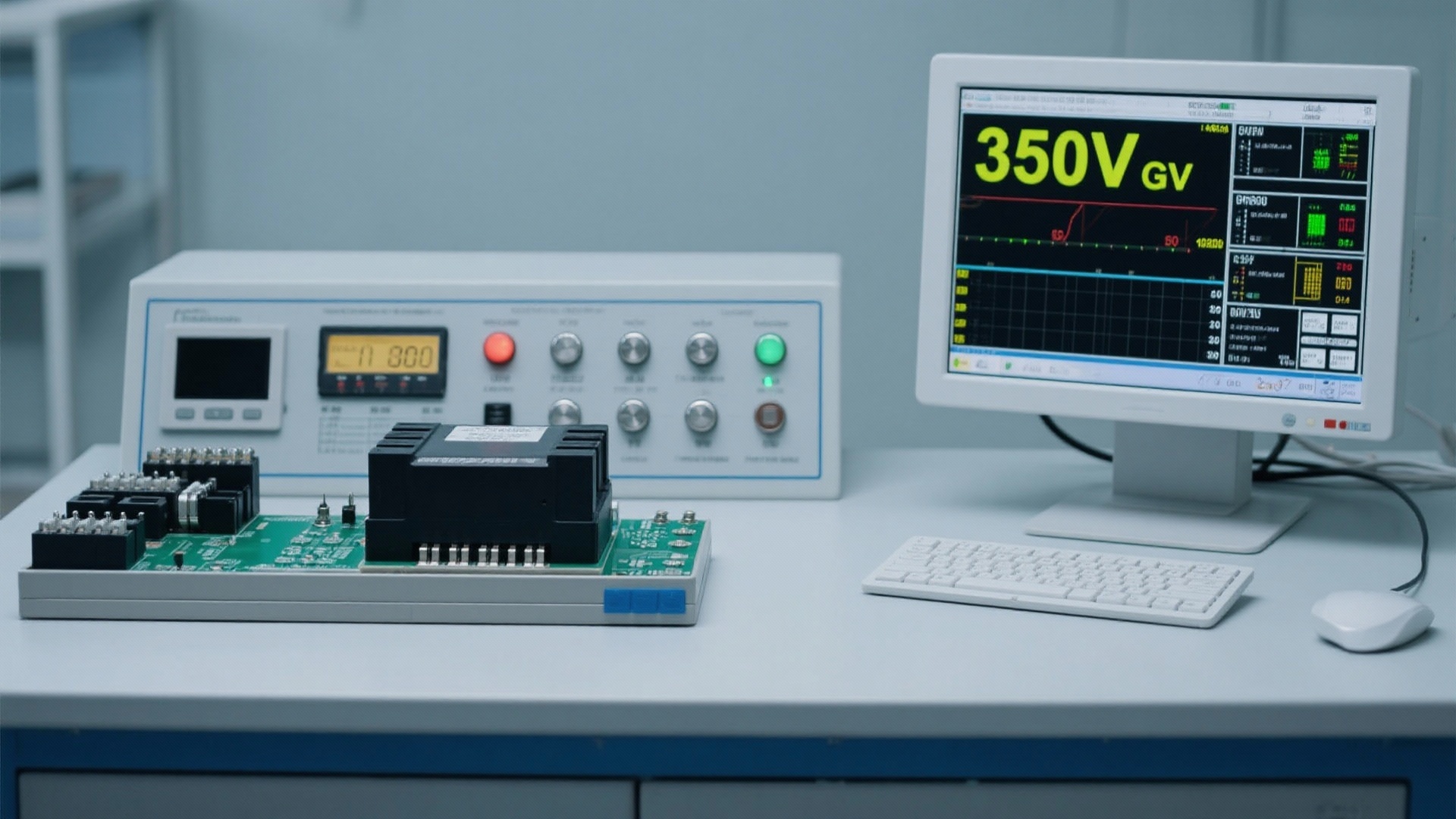

Test setup and measurement methodology

Point: Reproducible switching characterization requires a standardized double‑pulse or clamped‑inductive setup and careful probing. Evidence: Recommended practice includes a double‑pulse with a known inductive load, low‑inductance current shunt at the device source, Kelvin scope probes on gate and collector, and properly terminated measurement grounds to avoid capacitive coupling artifacts. Explanation: Key probe points: gate waveform (to capture Miller plateau and gate charge), collector voltage (Vce), device current (Is), and diode current return path. Gate‑drive settings (Vge_on/off, soft‑drive delays) must be documented. Actionable: Record Esw_on and Esw_off by integrating instantaneous v×i during transitions; log measurement bandwidth and probe compensation to ensure repeatability.

Turn-on/turn-off energy and loss comparisons

Point: Compute Esw_on and Esw_off from measured waveforms and compare aggregated switching loss across topologies. Evidence: Esw = ∫ vC(t) × iC(t) dt during the respective transition windows; total switching loss = Esw_on × fsw + Esw_off × fsw. Explanation: Example: if Esw_on+Esw_off for IGBT+Si diode = 10mJ per transition at 40A and IGBT+SiC SBD reduces combined Esw by 40%, then per‑device switching energy becomes 6mJ; at 20kHz that is 120W vs 200W per device. Actionable: Use the double‑pulse test to tabulate Esw vs Ic and Vbus for both diode types, and project system losses at intended switching frequency to size heatsinks and determine ROI.

EMI, dv/dt and system ripple effects

Point: Faster diodes with negligible recovery increase dv/dt during commutation; this impacts EMI and ring frequency. Evidence: Measured dV/dt during turn‑off and ringing spectra reveal peak amplitudes that couple into gate and control circuits through parasitic inductances and capacitances. Explanation: While eliminating Qrr reduces high‑amplitude current spikes, the more abrupt voltage transitions can raise high‑frequency content; designers must measure dV/dt, ringing frequency and common‑mode currents. Actionable: Capture both time‑domain and FFT spectra, and tune gate resistors, clamp snubbers, or add small RC snubbers to control peak spectral content while preserving switching efficiency.

Thermal performance, reliability & lifetime implications

Junction temperature, thermal resistance and derating

Point: Translate device power dissipation into junction temperature (Tj) and apply derating for continuous vs pulsed operation. Evidence: Tj = Tambient + Pd × Rth(j‑c) + Rth(c‑ua) etc.; datasheet gives Rth(j‑c) and maximum Tj. Explanation: Example calculation: For 30W device loss and Rth(j‑c) = 0.6 °C/W, junction rise above case = 18°C; include thermal interface material (TIM) and heatsink thermal resistance in full chain. Actionable: For continuous operation aim for Tj_max margin (e.g., keep Tj ≤ 125°C) and for pulsed loads allow higher transient Tj but verify thermal cycling limits through qualification testing.

Robustness: short-circuit, avalanche and transient behavior

Point: Short‑circuit withstand time and transient avalanche capability define protection needs. Evidence: IGBT short‑circuit behavior shows a defined tSC before device temperature rise causes failure if current not interrupted; pairing with SiC SBDs changes fault current paths and energy distribution. Explanation: Designers must characterize peak currents and energy absorption paths during faults: a non‑recovering diode can shift energy into the IGBT during some fault types, necessitating faster detection or tailored gate‑drive limits. Actionable: Perform controlled short‑circuit bench tests and confirm protection trips faster than device tSC, and ensure avalanche energy rating is not exceeded in expected transient conditions.

SiC SBD thermal stresses and package reliability

Point: SiC SBDs present different thermal cycling and solder fatigue profiles than silicon diodes. Evidence: SiC SBDs can operate at higher junction temperatures but repeatedly cycling between high power and standby creates solder fatigue and interconnect stress. Explanation: Layout choices that minimize thermal gradients, use proper thermal vias and copper pours, and select packages with proven solder joint reliability reduce long‑term failures. Actionable: Include thermal cycling testing (power cycling) and solder joint inspection in qualification; consult SiC vendor application notes for package‑specific guidance.

Integration & PCB / gate-drive design guidelines (method guide)

Gate drive tuning for GTSM40N065D in hybrid topologies

Point: Gate resistor selection and soft‑turn techniques balance switching loss, dV/dt and EMI for the GTSM40N065D. Evidence: Increasing Rg slows dV/dt and reduces ringing but increases turn‑on and turn‑off energy; active turn‑on/turn‑off profiles and Miller‑current handling are also important. Explanation: Recommended starting points: a low‑value Rg for turn‑on (to limit Vce rise time) and higher Rg for turn‑off, or a split‑resistor with a gate driver capable of toggling drive strength. Actionable: Tune Rg empirically: start with 5–10Ω and increase in steps while observing Esw and dV/dt until acceptable trade‑off between loss and EMI is reached; implement gate drive blanking as required to avoid false turn‑on from dV/dt coupling.

Snubber, clamp and freewheel design with SiC SBDs

Point: Snubber selection changes when using SiC SBDs due to reduced recovery events. Evidence: RC snubbers absorb voltage spikes, RCD clamps limit energy, and active clamps return energy to the bus; SiC SBDs often reduce the need for heavy RCD but can require optimized RC to tame dv/dt ringing. Explanation: Sizing weighs energy per switching event, allowable voltage overshoot and power dissipated in snubber. Actionable: Calculate snubber C by estimating the energy to be absorbed (E = 0.5 C ΔV^2), choose R to critically damp the LC ringing and ensure continuous dissipated power is acceptable or that an RCD/active clamp is used to recycle energy.

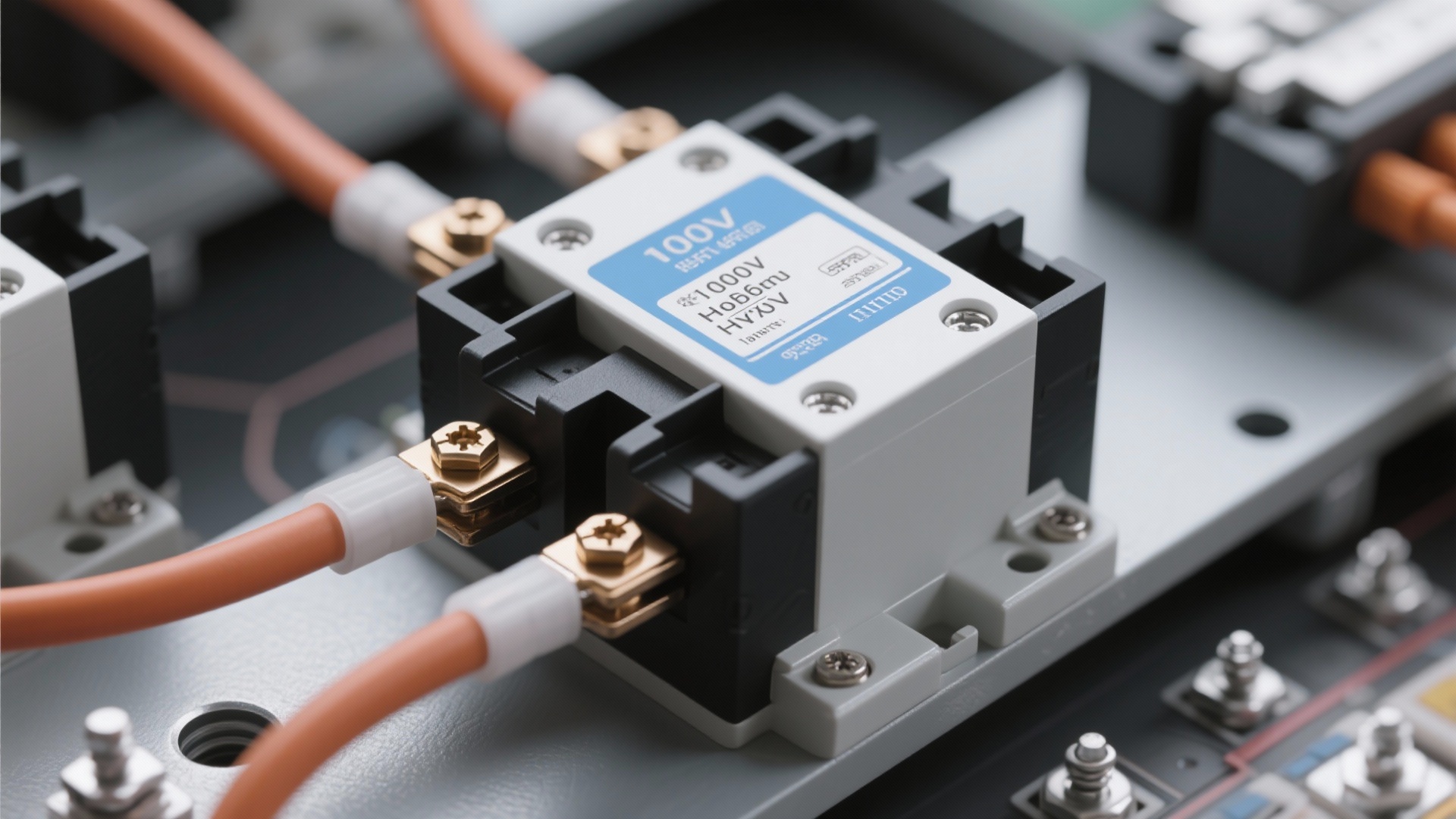

Layout, grounding and thermal PCB best practices

Point: Minimize loop inductance between IGBT and SBD, use Kelvin gate/source, and provide solid thermal vias for package heat spread. Evidence: Poor layout increases dV/dt coupling into the gate, raises EMI and can create localized hot spots. Explanation: Keep DC bus loops short and wide, place the SBD as close as possible to the IGBT freewheel node, use multiple thermal vias under packages and separate high‑current and signal grounds. Actionable: Implement Kelvin gate traces, low‑inductance shunt placement, and full copper pours with stitched vias to lower Rth and reduce switching loop inductance.

Comparative case study: measured results on a mid-voltage inverter block

Example system spec and test conditions

Point: Define a reference: 650V DC bus, 30A nominal, leg switching at 20kHz, ambient 40°C, using identical IGBT modules with either a fast Si diode or SiC SBD freewheel. Evidence: Measurements captured: efficiency vs load, Esw per transition (double‑pulse), conduction loss, heatsink temperature delta and EMI spectra. Explanation: Keeping measurements consistent (same gate drive profile and layout) isolates diode influence. Actionable: Use the double‑pulse to capture Esw at representative currents (10A, 20A, 30A) and project system losses across the load range to compute net efficiency improvement.

Loss and efficiency breakdown: IGBT-only vs IGBT+SiC SBD

Point: Typical benchmarks show 30–50% switching loss reduction and several percentage points net system efficiency improvement when moving to SiC SBD in the freewheel position. Evidence: Measured waveforms demonstrate lower turn‑off energy and reduced peak current spikes with SiC SBDs; heatsink steady‑state temperatures dropped correspondingly. Explanation: Example table content (recommended): per‑device Esw, conduction loss, total device dissipation and net inverter efficiency at 50% load. Actionable: Present measured waveform extracts alongside computed loss tables to justify BOM changes and cooling downgrades.

BOM, cost and manufacturability trade-offs

Point: SiC SBDs increase component cost but can reduce heatsink and system size, yielding ROI in volume or thermal‑constrained applications. Evidence: Incremental diode cost must be compared to savings from smaller cooling, higher efficiency and potential system downsizing. Explanation: Consider assembly implications: different packages, soldering profiles and supply chain lead times for SiC parts. Actionable: Run a simple payback model: quantify incremental diode cost, reduced heatsink cost and efficiency gains to decide whether SiC adoption is justified for the target production volume.

Practical action checklist for designers & next steps (action-oriented)

Quick wins for prototyping

Point: Start with gate‑drive tweaks and layout adjustments to capture early gains. Evidence: Empirical tuning of gate resistor and small RC snubber reduces switching losses and ringing without hardware swaps. Explanation: Rapid checks include reducing interconnect inductance, validating Kelvin connections, and trying SiC SBDs on an evaluation board. Actionable: Implement these five quick actions: (1) tighten switching loop, (2) add Kelvin gate, (3) start Rg at 5–10Ω and tune, (4) fit small RC snubber (e.g., 100nF/10Ω) for damped transitions, (5) run quick double‑pulse comparisons.

Test & qualification checklist before production

Point: A rigorous set of tests prevents field failures. Evidence: Mandatory steps include double‑pulse bench characterization, thermal and power cycling, EMI compliance runs and controlled short‑circuit verification. Explanation: Document test matrix with ambient ranges, duty profiles and failure criteria. Actionable: Include specific items: power‑cycle test (junction ΔT cycles), thermal shock, full EMI pre‑scan, and short‑circuit device protection validation with documented trip times.

Supplier, sourcing and part selection tips

Point: Vet SiC SBD vendors for reliability data and consistent supply. Evidence: Look for vendor app notes on ruggedness, recommended mounting and SBD thermal limits, and request sample reliability data. Explanation: Match diode current rating to IGBT freewheel peak current and consider package thermal resistance when co‑locating on the board. Actionable: Ask suppliers for power cycling and solder‑joint qualifications, verify lead times, and choose parts with compatible mounting footprints to minimize PCB redesign.

Summary

- Pairing the GTSM40N065D with a SiC SBD typically reduces switching losses substantially and can improve inverter efficiency while lowering heatsink requirements when properly integrated and driven.

- Key actions: measure Esw with a controlled double‑pulse bench, tune gate resistors to balance dV/dt and loss, and optimize PCB layout to minimize switching loop inductance and thermal gradients.

- Designers should validate leakage, blocking margin and thermal cycling for the chosen SiC SBD and run short‑circuit and EMI checks before finalizing production choices.

Frequently Asked Questions

How should one measure GTSM40N065D switching loss with a SiC SBD present?

Measure with a calibrated double‑pulse or clamped‑inductive setup: capture gate waveform (for Miller plateau), device current (low‑inductance shunt) and Vce with Kelvin‑compensated probes. Integrate instantaneous v×i across clearly defined turn‑on and turn‑off windows to produce Esw_on and Esw_off; repeat at multiple currents and temperatures to project system loss at target switching frequency.

What gate‑drive tuning steps reduce EMI while preserving efficiency for GTSM40N065D?

Start with modest gate resistance (5–10Ω) and incrementally raise Rg while monitoring Esw and dV/dt. Consider split‑resistor or active strength control to apply strong turn‑on and softer turn‑off. Add small RC snubbers or adjust clamp timing only if ringing exceeds acceptable EMI thresholds; always retest Esw after each change to track trade‑offs.

Which thermal tests are essential when using SiC SBDs with the GTSM40N065D?

Essential tests include steady‑state thermal profiling under full load, power‑cycle (thermal cycling) to evaluate solder fatigue, and thermal shock to reveal mechanical stress failures. Verify junction temperatures under worst‑case ambient and worst‑case switching/conduction losses to ensure long‑term reliability.

- Technical Features of PMIC DC-DC Switching Regulator TPS54202DDCR

- STM32F030K6T6: A High-Performance Core Component for Embedded Systems

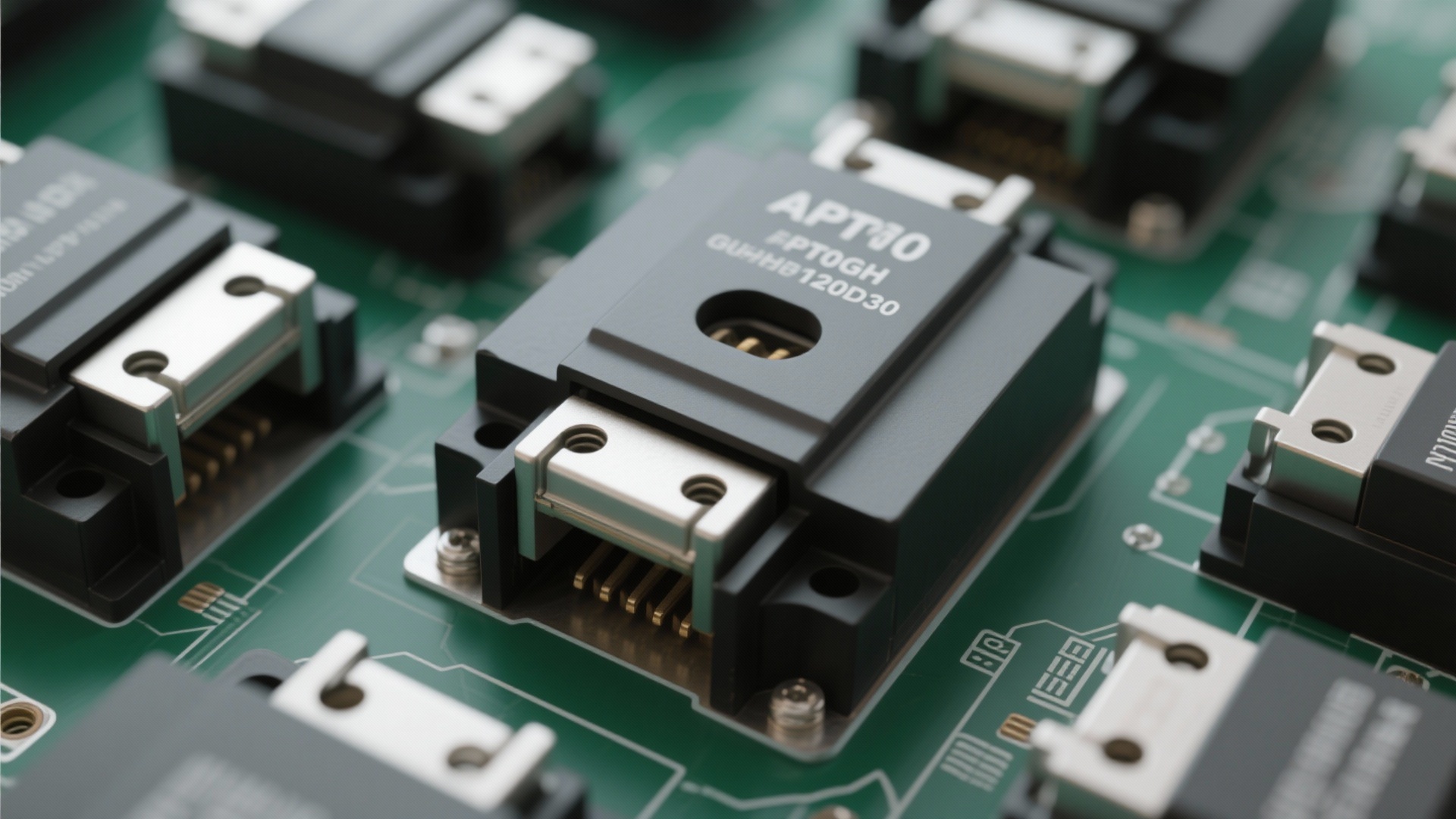

- APT50GH120B Datasheet Deep Dive: Specs, Ratings & Curves

- APT50GH120BSC20 Power Module: Latest Performance Report

- APT50GH120BD30 IGBT: How to Maximize Efficiency for EV Drive

- GTSM20N065: Latest 650V IGBT Test Report & Metrics

- CMSG120N013MDG Performance Report: Efficiency & Losses

- GTSM40N065D Technical Deep Dive: 650V IGBT + SiC SBD

- NOMC110-410UF SO-16: Live Stock & Price Report

-

MM74HC4050NonsemiIC BUFFER NON-INVERT 6V 16-PDIP

MM74HC4050NonsemiIC BUFFER NON-INVERT 6V 16-PDIP -

MM74HC4049NonsemiIC BUFFER NON-INVERT 6V 16-PDIP

MM74HC4049NonsemiIC BUFFER NON-INVERT 6V 16-PDIP -

MM74HC4040NonsemiIC BINARY COUNTER 12-BIT 16DIP

MM74HC4040NonsemiIC BINARY COUNTER 12-BIT 16DIP -

MM74HC4020NonsemiIC BINARY COUNTER 14-BIT 16DIP

MM74HC4020NonsemiIC BINARY COUNTER 14-BIT 16DIP -

MM74HC393NonsemiIC BINARY COUNTR DL 4BIT 14MDIP

MM74HC393NonsemiIC BINARY COUNTR DL 4BIT 14MDIP -

MM74HC374NonsemiIC FF D-TYPE SINGLE 8BIT 20PDIP

MM74HC374NonsemiIC FF D-TYPE SINGLE 8BIT 20PDIP -

MM74HC373NonsemiIC D-TYPE TRANSP 8:8 20-PDIP

MM74HC373NonsemiIC D-TYPE TRANSP 8:8 20-PDIP -

LT1213CS8Analog Devices Inc.IC OPAMP GP 2 CIRCUIT 8SO

LT1213CS8Analog Devices Inc.IC OPAMP GP 2 CIRCUIT 8SO -

MM74HC259NonsemiIC D-TYPE ADDR 1:8 16-PDIP

MM74HC259NonsemiIC D-TYPE ADDR 1:8 16-PDIP -

MM74HC251NonsemiIC MULTIPLEXER 1 X 8:1 16-PDIP

MM74HC251NonsemiIC MULTIPLEXER 1 X 8:1 16-PDIP